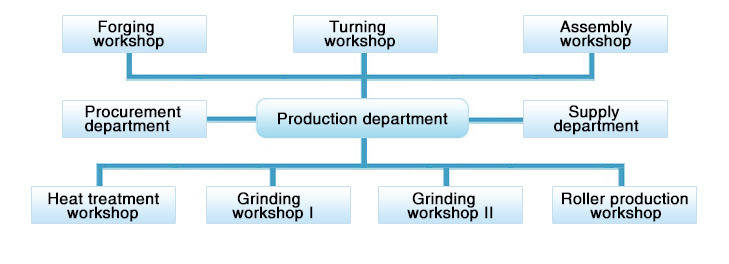

Main factory area : grinding processing, heat treatment, assembly

Factory in south area: material preparation, forging, annealing

Factory in high-tech park: slewing support and turntable bearings, high-precision heavy machinery bearings, etc.

|

|

|

|

|

|

YWY main technological equipment level

1.Material preparation and forging equipment and technological level

The company adopts sawing and cutting, has advanced precision high-speed upsetting machine, high-precision hot rolling and isothermal spheroidizing annealing process, 100% of special-shaped tire film, stress distribution is more reasonable, and the product parts have good metal flow lines. The annual forging workshop can produce more than 10,000 tons of various bearing forgings.

2.Car processing equipment and technological level

The company has a professional lathe processing workshop, with more than 120 various lathes, with a CNC rate of 90%. The turning process adopts a special numerical control lathe to improve the modeling accuracy. The lead angle and oil groove adopt numerical control imitation turning, and the turning instead of grinding process is adopted to reduce the amount of grinding. The super-large adopts CNC vertical turning technology, which is precise in shape and improves labor productivity.

|

|

3.Heat treatment equipment and technological level

The company has advanced multi-purpose furnace quenching and tempering production line with advanced heat treatment equipment of Aixielin; nitrogen-based protective atmosphere, salt bath isothermal quenching technology. Realize the bainite quenching process of rolling mill bearings, improve the stress state of the bearing surface, and increase the life of the bearing.

There are 8 large bearing carburizing pit furnaces, the maximum diameter of the ferrule that can be processed is 2200mm, the carburizing adopts oxygen probe and carbon potential instrument control, all realize computer simulation online centralized control, and realize full digital intelligent control.

4.Grinding processing equipment and technological level

The company has three grinding and processing workshops, grinding workshop one, grinding workshop two, and grinding and rolling workshop; it has more than 260 sets of various grinding and processing equipment, with an output value of 300 million yuan processing capacity. Grinding equipment adopts numerical control grinding machine and numerical control grinding production line, high-speed grinding numerical control technology, numerical control vertical multi-face grinding technology, inner and outer raceways, rolling bodies and other working surfaces realize convexity processing, and can control the shape of busbar, ferrule, roller Convexity ultra-precision process. The roller end face and crown are super-finished technology, and the rolling element processing level reaches the second level or above.

5.Turntable and wind power slewing bearing equipment

The company's high-tech park turntable bearing factory has more than 20 high-precision CNC machining equipment, such as high-precision CNC vertical lathes, drilling and milling machines, gear shaper milling machines, induction hardening and CNC vertical mills, and assembly testing tables, which can process various types of Φ800~Φ4000mm Medium and large turntable and slewing support bearings.